Industry 4.0 and controlled tightening

4.0 INDUSTRY DEFINITION

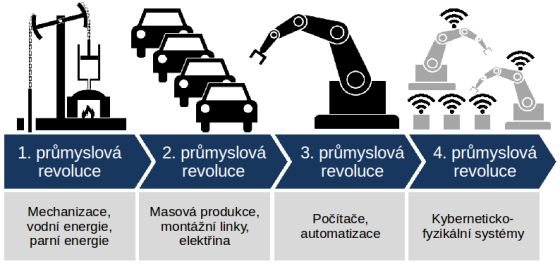

The fourth industrial revolution is currenly being implemented. It is characterised by the use of information and communication technologies in the working environment. Industry 3.0 is the cornerstone. Machines are complemented by network connections and the Internet. The connection of all these machines to the network leads to the creation of "cyber-physical production systems". Industry 4.0 is the label for the future transformation and innovation of production processes. Digitalisation and the internet will enable all production processes and services to be completely connected and automatised. When we talk about Industry 4.0, we are talking about so-called "smart factories". Only precisely set up pre-production processes will allow companies to run automated factories perfectly, where people communicate via the network and production is almost autonomous.

Current trends in production :

- Internet of things

- Artificial Intelligence

- Cloud

- Big Data

- System Engineering

- Drawingless Manufacturing

- Reverse Engineering

- Additive Manufacturing

By using the new Industry 4.0 tools and methods, companies should save money, time and increase flexibility. A fast network and quality hardware are needed to function well, as the main risks include hacker attacks or data misuse. It will also bring the hope of improving the quality of human life and the disappearance of physically demanding professions.